Chogulitsa chabwino sichimangokonzedwa, komanso chimafunikanso chithandizo chamankhwala chosiyanasiyana kuti chiteteze ku dzimbiri, kukana kuvala, kukongola, ndikuwonjezera moyo wautumiki.RCT MFG ili ndi zaka zambiri mu CNC processing ndi jekeseni akamaumba processing, amaperekanso mndandanda wa ntchito kuchokera processing kuti pamwamba mankhwala kusonkhana.Chifukwa chake, kuphatikiza paukadaulo wopanga, amakhalanso ndi chidziwitso chochuluka pazamankhwala apamwamba.The alipo pamwamba mankhwala njira monga: kupenta, Kuphika utoto, ❖ kuyanika ufa, sandblasting, kuwombera kuphulika, anodizing, wandiweyani filimu anodizing, yaying'ono-arc anodizing, electroplating, electrophoresis, laser chosema, silika chophimba kusindikiza, brushed zitsulo, galasi kupukuta, utoto, blackening, CD pattern, etching, high gloss, etch pattern, Epoxy, etc., zimathandiza kupanga malonda anu pamlingo wapamwamba.

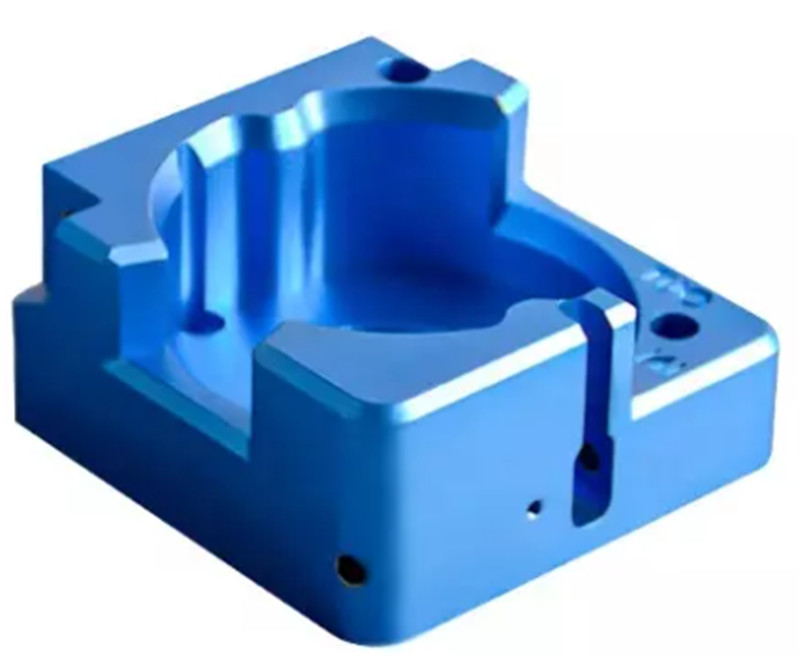

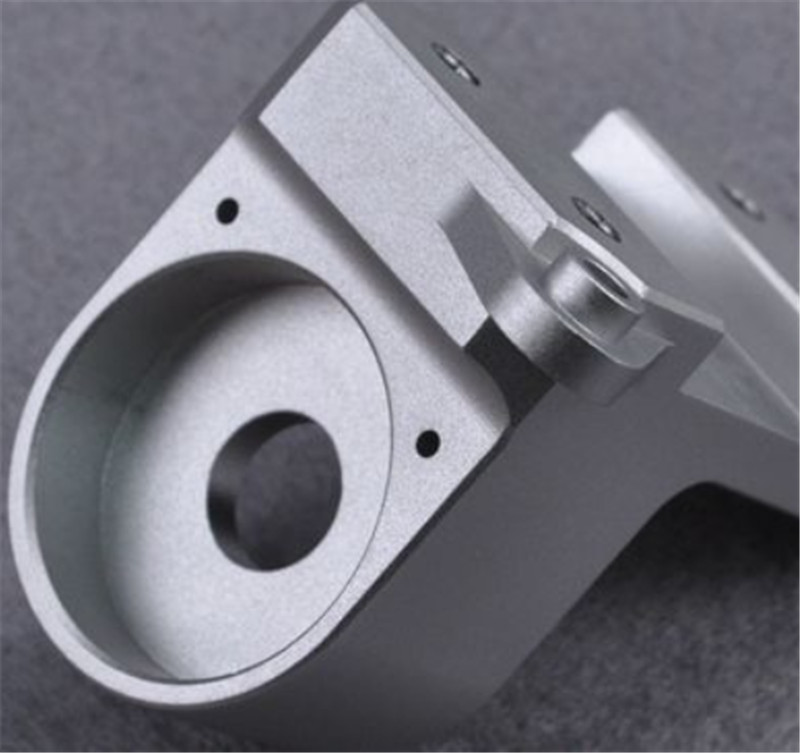

Anodizing

Ndi njira ya electrolytic oxidation, yomwe imasintha pamwamba pa zinthuzo kukhala filimu yoteteza, zomwe zimapangitsa kuti zikhale zovuta kutulutsa oxidize ndi corrode, kutalikitsa moyo ndi kukwaniritsa maonekedwe a mitundu yosiyanasiyana.Ambiri ntchito anodizing mankhwala anawagawa: wamba anodizing , brushed zitsulo anodizing, molimba anodizing, wandiweyani filimu anodizing, yaying'ono-arc makutidwe ndi okosijeni, etc. The zipangizo zomwe oxidized ndi: zotayidwa aloyi, magnesium aloyi, titaniyamu aloyi, etc.

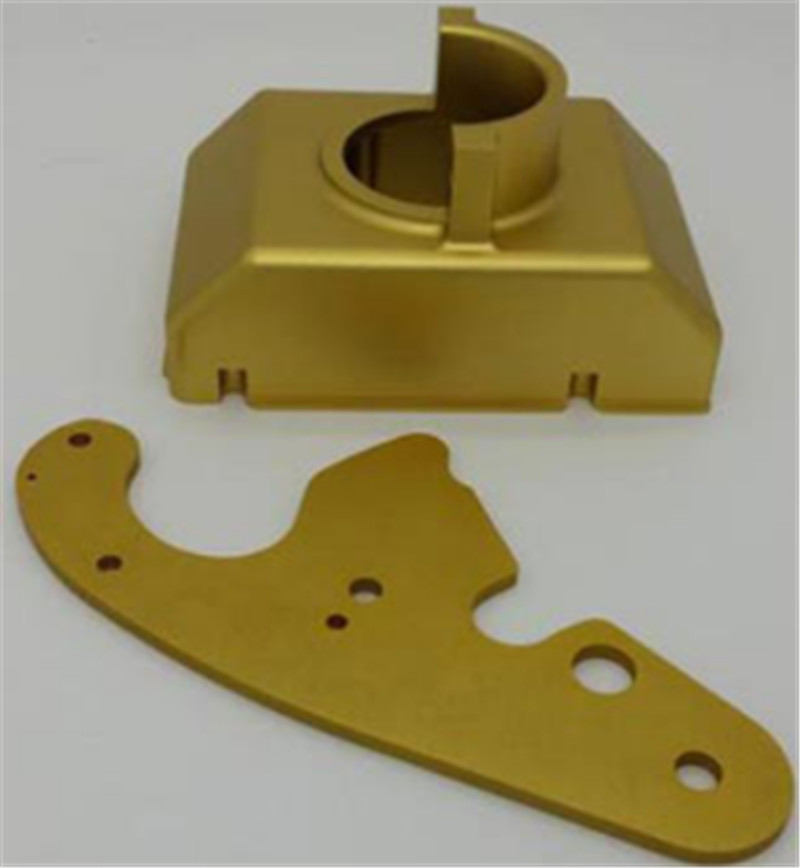

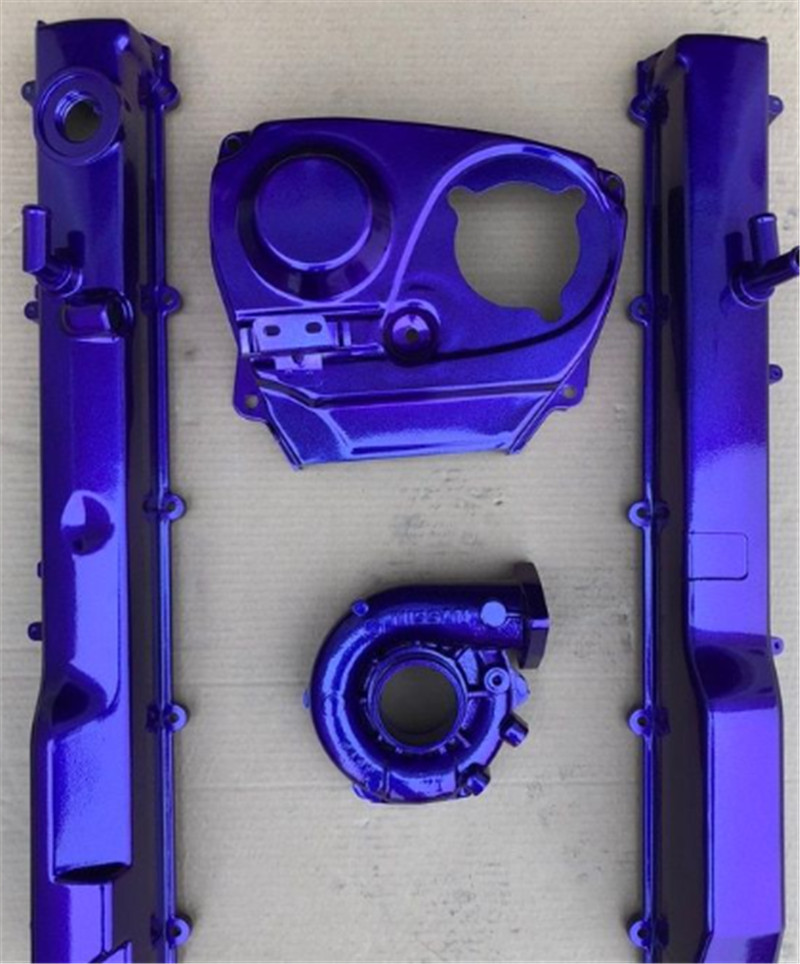

Electroplating

Njira yaikulu ya electroplating ndi kumiza gawo mu njira ya mchere wachitsulo monga cathode, ndi mbale yachitsulo monga anode, ndikudutsa panopa kuti muyike ❖ kuyanika komwe mukufuna pa gawolo.Mphamvu yoyenera ya electroplating ipangitsa kuti malonda anu akhale apamwamba komanso apamwamba.Kumsika wabwinoko, electroplating yokhazikika imaphatikizapo plating yamkuwa, nickel plating, plating siliva, plating golide, chrome plating, galvanizing, malata plating, vacuum plating, etc.

Electrophoretic zokutira

Ndikusintha kosalekeza kwa kufunikira kwa mafakitale, ukadaulo wa Electrophoretic wokutira umatha kusintha mitundu yosiyanasiyana, kukhalabe ndi zitsulo zonyezimira komanso kukulitsa kukana kwa dzimbiri pamtunda, zomwe sizikhudza kulondola kwazinthu.Makulidwe ake ndi pafupifupi 10-25um, ndipo zokulirapo zimathanso kusinthidwa

Passivation

Passivation, yomwe imadziwikanso kuti chromate treatment, ndi njira yowonongeka yomwe imachotsa mafuta pamwamba, dzimbiri, ndi ma oxides mwa kumiza kapena kuyeretsa ndi akupanga.Kudzera mankhwala anachita ya passivation njira, izo zingalepheretse dzimbiri ndi kutalikitsa dzimbiri.Mtundu wa filimu ya passivation udzasintha ndi zipangizo zosiyanasiyana.Passivation sichidzawonjezera makulidwe a mankhwalawa, ndipo palibe chifukwa chodandaula kuti zimakhudza kulondola kwa mankhwalawo.

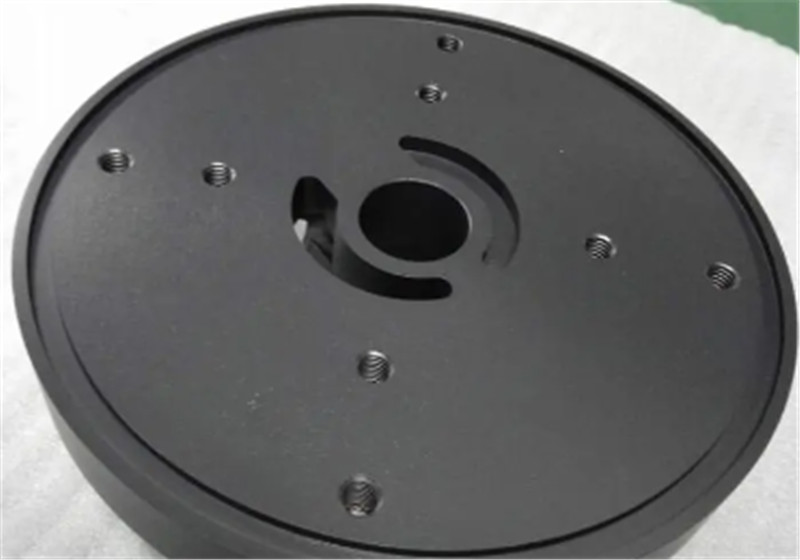

Wadetsedwa

Blackening imatchedwanso bluing.Mfundo ndi kumiza mankhwala mu amphamvu oxidizing mankhwala njira kupanga okusayidi filimu pamwamba zitsulo kudzipatula ndi kukwaniritsa cholinga kupewa dzimbiri.Njirayi ikugwiritsidwa ntchito pazinthu zachitsulo.

QPQ (Quench-Polish-Quench)

Amatanthauza kuika ziwalo zachitsulo zachitsulo mumitundu iwiri yamadzi osambira amchere okhala ndi zinthu zosiyanasiyana, ndikulowetsa zinthu zosiyanasiyana muzitsulo zachitsulo kuti zipange kusanjikiza kophatikizana, kuti akwaniritse cholinga chosintha pamwamba pa zigawozo.Ili ndi kukana kwabwino kovala, kukana kutopa, kukana dzimbiri komanso kusinthika pang'ono.Njirayi ikugwiritsidwa ntchito pazinthu zonse zachitsulo.

(Zindikirani: Zopangira zitsulo zosapanga dzimbiri sizingadetsedwe, ndipo pamwamba pake zitha kukhala zakuda ndi QPQ)

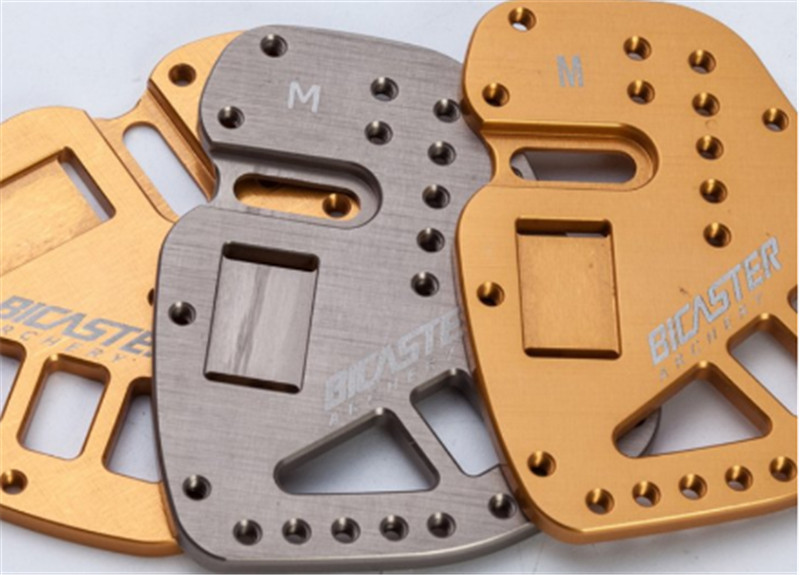

Laser engraving

Laser engraving, yomwe imatchedwanso chizindikiro cha laser, ndi njira yochizira pamwamba pogwiritsa ntchito mfundo za kuwala kuti apange Logo kapena mapatani pazinthu.Laser chosema zotsatira ndi okhazikika, pamwamba khalidwe ndi apamwamba, ndipo ndi oyenera zinthu zopangidwa ndi zitsulo zosiyanasiyana ndi pulasitiki zipangizo.

Silika chophimba kusindikiza

Kusindikiza pansalu ya silika kumatanthauza kuti inki imasamutsa pateni kupita ku chinthucho kudzera pazenera.Mtundu wa inki ukhoza kusinthidwa malinga ndi zosowa za makasitomala.RCT MFG yapanga mitundu ya 6 pazinthu zomwezo, kuphatikiza zakuda, zofiira, zabuluu, zachikasu ndi zoyera., green.Ngati mukufuna kuti zotsatira za kusindikiza kwa nsalu za silika zikhale zolimba, mutha kuwonjezeranso wosanjikiza wa UV pambuyo pa kusindikiza kwa silika kuti mutalikitse moyo wake.Kusindikiza kwa silika ndi koyenera pazinthu zosiyanasiyana zachitsulo ndi pulasitiki, komanso kutha kuphatikizidwa ndi chithandizo chapamwamba monga makutidwe ndi okosijeni, utoto, kupopera mbewu mankhwalawa ufa, electroplating, ndi electrophoresis.

Kupukutira

Kupukuta ndikupangitsa kuti chinthucho chikhale chokongola, chowoneka bwino komanso kuteteza pamwamba.Kupukuta ndi kuwonekera ndi chisankho chabwino kwa inu.Kupukuta kwa zinthu za Hardware kumagawidwa kukhala kupukuta kwamanja, kupukuta kwamakina, ndi kupukuta kwa electrolytic.Electrolytic polishing ingagwiritsidwe ntchito m'malo mwa kupukuta kwamakina olemera, makamaka kwa magawo omwe ali ndi mawonekedwe ovuta komanso magawo omwe ndi ovuta kuwakonza pogwiritsa ntchito kupukuta kwamanja ndi njira zamakina.Electrolytic kupukuta nthawi zambiri amagwiritsidwa ntchito pazitsulo, aluminiyamu, mkuwa ndi mbali zina.

Brushed Metal

Chitsulo chopukutidwa ndi njira yochizira pamwamba yomwe imapanga mizere pamwamba pa chogwirira ntchito kudzera pa lamba wamba woponderezedwa komanso burashi yopanda nsalu kuti ikwaniritse zokongoletsa.Chithandizo cha brushed pamwamba chikhoza kusonyeza maonekedwe a zitsulo zachitsulo, ndipo akukhala otchuka kwambiri m'moyo wamakono.Amagwiritsidwa ntchito kwambiri pama foni am'manja, makompyuta, zowunikira, mipando, zida zamagetsi ndi zipolopolo zina.

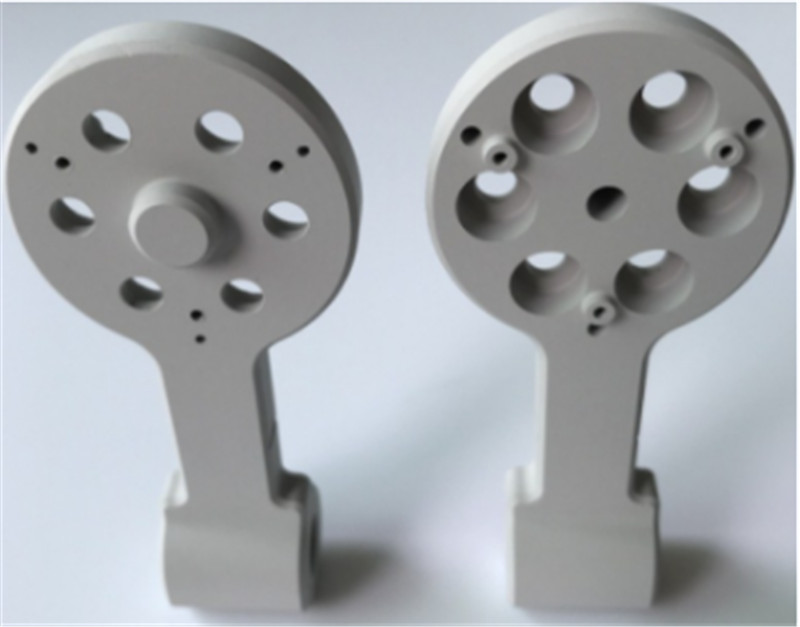

Kupopera utoto ndi kupopera ufa

Kupopera penti ndi kupopera ufa ndi njira ziwiri zochizira pamwamba pazigawo za hardware, ndipo ndizomwe zimagwiritsidwa ntchito kwambiri pazigawo zolondola komanso kusintha makonda ang'onoang'ono.Amatha kuteteza pamwamba pa dzimbiri, dzimbiri, komanso amatha kukwaniritsa zokongoletsa.Kupopera mbewu ndi kupenta kungathe kusinthidwa ndi maonekedwe osiyanasiyana (mizere yabwino, mizere yokhotakhota, mizere yachikopa, ndi zina zotero), mitundu yosiyanasiyana, ndi milingo yowala yosiyana (matte, flat, high-gloss).

Kuphulika kwa mchenga

Sandblasting ndi imodzi mwa njira zochizira pamwamba pa zinthu za hardware.Ikhoza kusintha ukhondo ndi roughness, ndi kuonjezera adhesion ndi durability pakati mankhwala ndi zokutira.Choncho, mankhwala ambiri apamtunda amasankha sandblasting ngati mankhwala awo oyambirira.Monga: sandblasting + oxidation, sandblasting + electroplating, sandblasting + electrophoresis, sandblasting + fumbi, sandblasting + penti, sandblasting + passivation, etc.

Kupopera mbewu mankhwalawa Teflon

Amatchedwanso kupopera mbewu mankhwalawa kwa Teflon, ndi mankhwala apadera kwambiri padziko lapansi.Ili ndi mawonekedwe apamwamba a anti viscosity, non viscosity, kukana kutentha kwambiri, kukangana pang'ono, kuuma kwakukulu, kusanyowa, komanso kukana kwa mankhwala.Choncho, chimagwiritsidwa ntchito makampani chakudya, tableware, kitchenware, makampani pepala, zipangizo zachipatala, mankhwala pakompyuta ndi katundu galimoto, zida mankhwala, etc., ndipo akhoza kuteteza zipangizo ku dzimbiri mankhwala kuwonjezera moyo utumiki wa mankhwala.

Etching

Etching ndi njira yochotsera zinthu pogwiritsa ntchito mankhwala kapena kukhudza thupi.Kawirikawiri amatanthauza etching, yomwe imadziwikanso kuti photochemical etching, yomwe imatanthawuza kuchotsa filimu yoteteza m'deralo kuti ikhale yokhazikika pambuyo popanga mbale ndi chitukuko, ndi kukhudzana ndi njira yothetsera mankhwala panthawi ya etching kuti akwaniritse zotsatira za kusungunuka ndi dzimbiri, kupanga zotsatira za concave-convex kapena dzenje akamaumba.

IMD

Mu Kukongoletsa Mold (IMD) ndi njira yotsika mtengo yokongoletsa mbali zapulasitiki.Zili ndi masitepe anayi: Kusindikiza, Kupanga, Kudula ndi Kupanga jekeseni.Ndipo ndiukadaulo wodziwika padziko lonse lapansi wokongoletsa pamwamba.Pamwamba ndi owumitsidwa ndi mandala filimu, pakati kusindikiza chitsanzo wosanjikiza, kumbuyo jekeseni akamaumba wosanjikiza, ndi pakati pa inki akhoza kupanga mankhwala kugonjetsedwa ndi mikangano., zimateteza pamwamba kuti zisakulidwe, ndipo zimatha kusunga mtunduwo kuti ukhale wowala komanso wosavuta kuzimiririka kwa nthawi yayitali.

Pad Printing

Kusindikiza kwa pad, komwe kumatchedwanso tampography kapena tampo printing, ndi njira yosindikizira yosalunjika (gravure) pomwe silicon pad imatenga chithunzi cha 2-D kuchokera pa mbale yosindikizira ya laser (etched) (yomwe imatchedwanso cliché) ndikuitumiza ku 3- D chinthu.Chifukwa cha kusindikiza kwa pad, tsopano ndizotheka kusindikiza mitundu yonse ya zinthu zovuta zooneka ngati zopindika (zopingasa), zosanjikizana (zopindika), zozungulira, zozungulira, ma angles apawiri, mawonekedwe, ndi zina zomwe sizinalipo ndi njira zachikhalidwe zosindikizira.

Kusindikiza kwa transfter yamadzi

Kusindikiza kwa madzi ndi mtundu wa kusindikiza komwe kumagwiritsa ntchito kuthamanga kwa madzi kuti hydrolyze pepala losamutsa / filimu yapulasitiki yokhala ndi mitundu yamitundu.Njira yaukadaulo imaphatikizapo kupanga mapepala osindikizira otumiza madzi, kuviika mapepala amaluwa, kusamutsa patoni, kuyanika, ndi kumaliza.

Kuphimba kwa conductive

Conductive coating ndi mtundu wa utoto womwe ungagwiritsidwe ntchito kupopera mbewu mankhwalawa.Imatha kuyendetsa magetsi ikayanika kuti ipange filimu ya utoto, kuti iteteze kusokoneza kwa ma elekitiroma.Pakali pano, amagwiritsidwa ntchito m'mafakitale ambiri ankhondo ndi aboma monga zamagetsi, zida zamagetsi, ndege, makampani opanga mankhwala, kusindikiza, etc.

Nthawi yotumiza: Apr-11-2023